TECHINCAL SAFETY

We provide Services in the field of Process Safety Management, Risk and HSE management to the energy sector, chemical and petrochemical sector and utilities provider sector. Our highly experience technical team will identify the risk in the system, assess the adequacy of the existing safeguards and recommend mitigative or preventive measures to avoid/control/reduce the risks involved.

Process Safety Management (PSM)

Process Safety Management (PSM), provides a systematic approach to proactively managing risks associated with hazardous processes. It doesn’t rely on reacting to incidents, but instead implements measures like hazard identification, control procedures, training, and incident investigation to prevent them entirely.

It reduces accident risks through proactive hazard identification and controls, safeguarding lives and preventing costly disruptions. Adhering to regulations avoids fines and protects your business, while optimized processes and minimized downtime from incidents boost productivity and profitability. More than that, a strong safety culture built on communication fosters trust and engagement, leading to a happier, more productive workforce.

We are experienced to provide our services in the following areas:

- Functional Safety

As a part of functional Safety our experts will help our clients to enhance operational reliability, protect valuable assets, and promote a culture of safety within your organization. Our Functional Safety service in the process industry is designed to help businesses ensure the reliable operation of their safety-critical systems. Through a comprehensive assessment of the system architecture, safety requirements, and risk analysis, we help identify potential hazards and implement appropriate safety measures.

- Process safety management audits.

We offer ongoing support, conducting regular audits to ensure the effectiveness of your PSM program

- Process safety gap assessment

Our involvement will proactively address potential safety gaps and protect operations, employees, and reputation. Our engineers will help our clients to identify and bridge gaps in their process safety management systems. Through this assessment, our clients gain a clear understanding of their current safety performance and receive tailored recommendations to enhance their process safety practices.

- Process safety training development and delivery.

We guide you through the implementation process, providing comprehensive training for your personnel.

- Process safety management systems design, implementation and maintenance.

We tailor a program that aligns with your specific risks, industry standards, and organizational goals.

- Hazardous Area Classification

For every projects we ensure the utmost safety in hazardous environments while specifying the instruments, electrical equipment. Our engineers are specialized in evaluating and classifying areas with potentially explosive atmospheres, helping businesses mitigate risks and comply with regulatory requirements. Our team of experts will conduct thorough assessments of your facility, identify hazardous zones, and recommend appropriate safety measures and equipment.

Risk Management

- HAZID (Hazard Identification)

HAZID is a workshop-based qualitative risk analysis technique commonly used for the identification of potential hazards and threats in a process.

Our experts can review the process at an early stage with a view to ensuring that the process design accounts for credible hazardous scenarios and review safeguards included in the design of the process which are designed to mitigate the relevant risk from all possible hazards including natural calamities.

- HAZOP (Hazard and Operability)

HAZOP study is a systematic way to identify hazards in the system, find causes, consequences and existing safeguards. If the safeguards are not adequate recommendations are given to mitigate the risk. The study is conducted and participated by company personnel and our HAZOP Facilitator with scribe.

If we are appointed to carry out HAZOP study for the facility, we will help client to manage the comprehensive HAZOP Study to identify and mitigate potential hazards in their industrial processes. Our experienced team will analyze your operations, systematically identify deviations, and propose effective control measures. With our HAZOP Study services, clients can achieve improved safety protocols, reduced operational risks, and enhanced compliance with regulatory standards.

- LOPA (Layer of Protection Analysis /SIL (Safety Integrity Level) Assessments

Our specialized experts will assess the adequacy of protection layers using powerful analytical tool Layers of protection analysis (LOPA) and provide recommendations to mitigate process risks in the installation. LOPA builds upon well-known process hazards analysis techniques, applying semi-quantitative measures to the evaluation of the frequency of potential incidents and the probability of failure of the protection layers.

We specialize in providing Safety Integrity Level (SIL) services to businesses aiming to enhance the safety and reliability of their critical systems. Our expert team helps clients achieve the desired Safety Integrity Level by conducting comprehensive assessments, evaluating potential risks, and recommending appropriate risk reduction measures.

- Quantitative Risk Assessment (QRA)

Quantitative Risk Assessment (QRA) is a critical service with our expertise in risk analysis, we help businesses evaluate and quantify safety risks associated with their operations. Risk is a combined effect of consequences (fire, explosion, flammable and toxic gas dispersion) and probability of the event and is expressed in terms of risk/ avg year. By conducting in-depth assessments and utilizing advanced methodologies, we enable our clients to make informed decisions and develop effective risk management strategies. The risk is benchmarked against the risk acceptance criteria of the country and accordingly the action is taken to mitigate the risk.

- Fire & Explosion Risk Analysis

This is a part of QRA which includes estimation of risk posed by fire and explosion of flammable material on the facility and surroundings. Our engineers will help our clients to assess the impact of thermal radiations and explosion overpressure on the surroundings and therefore helps in the decision making of various facilities such as facility siting, control room location, admin building location, fire protection adequacy etc.

- ALARP and Cost Benefit Analysis

The zone between the unacceptable risk and broadly acceptable risk regions is the tolerable region. Risks in that region are typical of the risks from activities that people are prepared to tolerate in order to secure benefits in the expectation that the residual risks are not unduly high and kept As Low As Reasonably Practicable (the ALARP principle).

Cost–benefit analysis (CBA) is a systematic approach estimating the strengths and weaknesses of mitigation measures that satisfy the reduction in the risk. It is a technique that is used to determine mitigation measures that provide the best approach for the adoption and practice in terms of benefits in reducing risk, severity, practicability of implementation and cost savings etc.

- Fire and gas detector location / mapping study

Our engineers will help our clients to decide the location of fire and gas detectors in the installation. Dispersion analysis with mapping study methodology is used to decide the no of detectors, location of detectors and type of detectors required in the facility.

- Escape, Evacuation & Rescue Analysis

Our engineers will assess the impairment of escape routes, evacuation and rescue locations in the emergency from fire and toxic gases. The vulnerability of human beings will be the criteria to analyse and define the impairment.

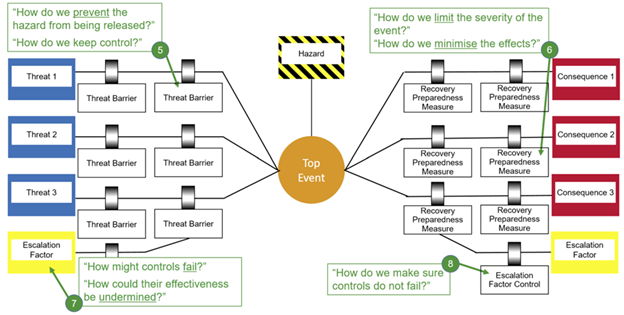

- Bow Tie Analysis

A bow tie analysis is a risk assessment methodology that is used to visualize the potential risk exposures and outcomes related to various hazard scenarios or events

This analysis is a visualization of the relationship between top hazard event, its causes, accidental scenarios, the preventive and mitigation measures to limit their consequences in a single image. It demonstrates the effectiveness of existing controls.

In this analysis, our engineers will identify the top hazard event which is considered in the middle of Bow. Further the consequences/ threats of the event will be identified on one hand and barriers/safety measures/preventive measures for each threat will be identified on another hand.

It is very effective risk analysis method where quantification of risk is not possible/ desired.

- Emergency Response and Disaster Management Plan (ERDMP)

Our engineers will help to prepare a manual which will have all details of Emergency Response, Preventive Measures and Disaster Management Plan to handle the situation.

Softwares being used

PHA Pro / HAZOP pro

PHAST and PHAST Risk